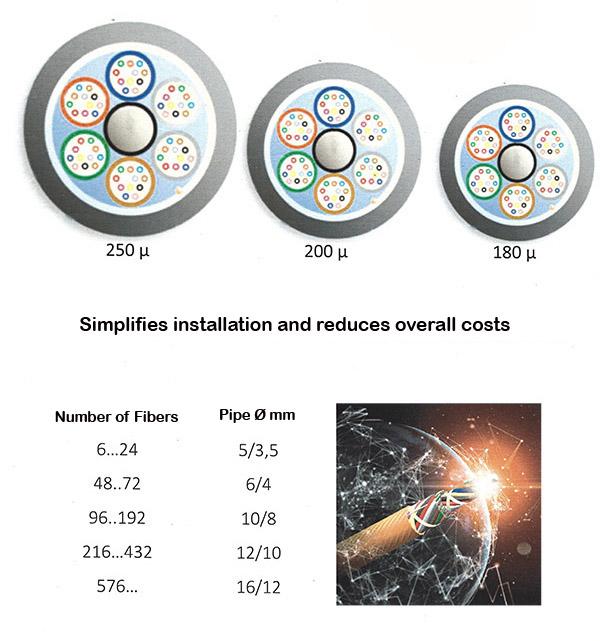

MICRODUCTS AND CONNECTORS FOR AIRBLOWN FIBER OPTICAL.

The main purpose of the application of HF microductssystem is to allow the usage of already existing duct systems ensuring their multiplying, and also to construct new urban microducts, fiber optic networks, including telecommunication networks, data transmission networks, television, monitoring networks.

HF Microducts are made of HDPE polyethylene, sheaths and covering pipes can be made of HDPE polyethylene or polypropylene PP

Direct installation 5/3.5 - 14 individual channels

Multi Ducts

Bundles of thin-walled microducts/DI WPW-MC in thin, tight sheath; with polygonal cross-section; designed to be installed in primary cable canalization (in primary pipes), or to fill already existing secondary tele-technical canalization, and to fill cable pipelines.

The configuration of the number and diameters of the microducts can be adjusted to a customer’s individual needs. The thin sheath, that can be removed, ensures easy separation and extraction of the individual microducts.

Bundles can be produced with locating wire (prefabricated inside) in order to localize the route of bundles in future. Standard color of the outer sheath – orange.

HFiberDUCT™

Multi Ducts

Direct Burial 7/4

2 single tubes

Multi Ducts

Bundles of thick-walled microducts WPW-MG in thin, tight sheath; with polygonal cross-section; designed for direct burying underground.

The configuration of the number and diameters of the microducts can be adjusted to a customer’s individual needs. The thin sheath, that can be removed, ensures easy separation and extraction of the individual microducts.

Bundles can be produced with locating wire (prefabricated inside) in order to localize the route of bundles in future.

Standard color of the outer sheath – orange.

HFiberDUCT™

Multi Ducts

Stiff pipes

25x2 2 single tubes

Multi Ducts

Bundles of thick-walled microducts WPW-MG in thin, tight sheath; with polygonal cross-section; designed for direct burying underground.

The configuration of the number and diameters of the microducts can be adjusted to a customer’s individual needs. The thin sheath, that can be removed, ensures easy separation and extraction of the individual microducts. Bundles can be produced with locating wire (prefabricated inside) in order to localize the route of bundles in future.

HFiberDUCT™

Multi Ducts

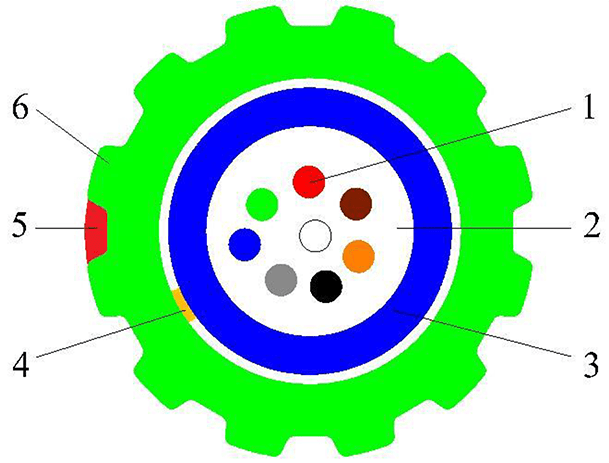

Single micro tube

Direct install 12/10

HFiberDUCT™

Multi Ducts

Multi Ducts

Thin-walled/DI microducts Micro MC are designed to fill already existing secondary tele- technical canalization, and to fill cable pipelines, including pipes partly occupied by the fiber optic cable. Made of high density polyethylene HDPE, with smooth inner surface (for diameters

< 7mm) or longitudinally grooved inner surface (for diameters > 7mm). Co-extruded inner surface is made of slippery material, with a very low coefficient of friction. Produced in full color or semi- transparent to facilitate the recognition of microducts filled with cables.